The goal is to improve the existing combustion concepts for glass furnaces. For this, the radiation of the flame is adjusted so that their energy is absorbed not only by the near-surface layers, but also penetrating deeper into the glass melt and the direct energy output of the flame can be adjusted to reach the area of the furnace, which requires the highest temperatures – the refining zone. This can be archieved combined with a reduced flame temperature. Long term tests have proven the Second Phase Firing (SPF) enables furnace operators to improve the energy balance thus creating energy-saving, reduced CO2 emissions and lowered NOx in order to meet todays emission standards.

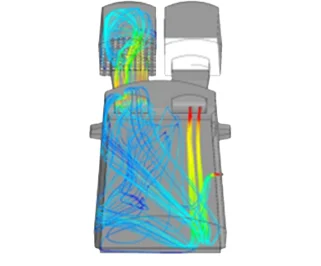

When installing the SPF system a more uniform temperature profile (lower temperatures at the start of the combustion and increased temperatures at the end) are achieved. by evening the temperatur in the furnace, hot spots are moving downstreams, increasing the refining temperature. By avoiding temperature peaks, the formation of thermal NOx is reduced. Local emisivity is increased by restricted soot formation. This soot is burned up until the entry of the exhaust gases into the regenerator, to prevent any damage to the chambers. Hotwork and UAS specialised in supply of auxiliary equipment, including full gas control stations, furnace control system ( DCS ), full automation, exhaust gas analysis and Oxygen probes as well as tuning, supervision and commissioning services worldwide.

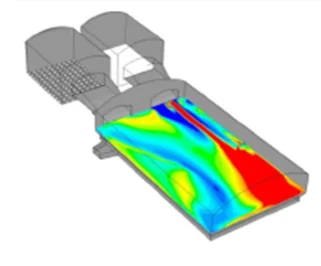

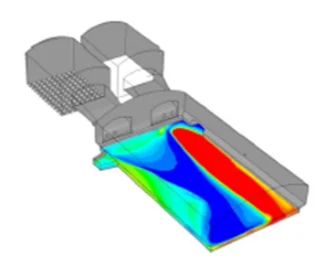

The image below shows that at the point at which the glass melt should reach the highest temperature (hot spot, refining zone) given the already reduced „flame“ temperature (for NOx reduction), the direct energy input of the flame is very low. To bring more energy into the glass tank at this point, it is necessary to raise the crown temperature or the direct input of energy by changing the flame control. An increase of the crown temperature is not a solution, as the refractory material limit temperature would be exceeded and the lifetime of the furnace would be endangered. With the SPF the temperature can be increased at this point, increasing the energy input and reducing NOx.