Cement

Dry out of refractory lining

Dry-out ensures the safe removal of moisture from newly installed refractory linings, preventing cracking or spalling due to thermal stress. This process enhances the durability and performance of linings in high-temperature areas like kilns and preheaters.

Read more about furnace dry out and heat up

Pre-Heater / Tower

In the Pre-heat tower, dry-out is crucial to gradually remove moisture from the refractory lining. This ensures even heat distribution and prevents thermal shock, which can compromise structural integrity.

Read more about pre heater tower

Cooler

Dry-out in the cooler removes residual moisture from the refractory and ensures uniform temperature control. This helps optimize cooling efficiency and protects the refractory lining from premature wear.

Read more about cooler

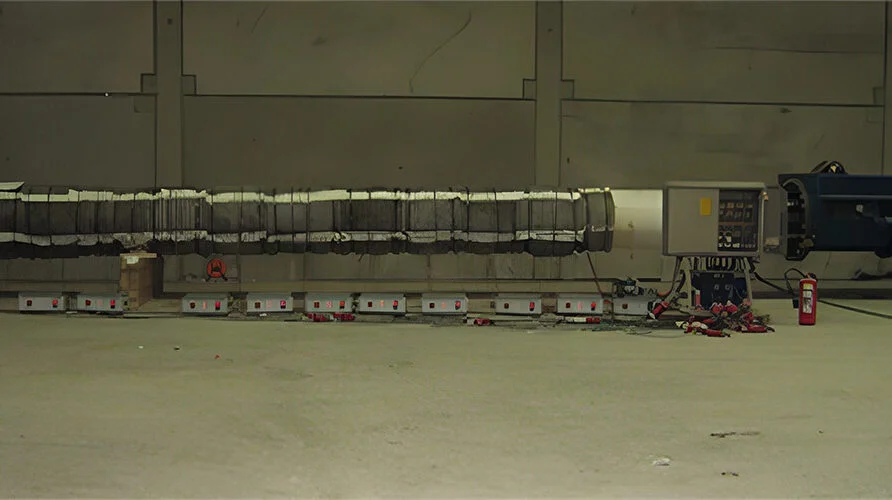

Mill Heating

Cement plant operators occasionally require a temporary heat source for mill testing and system commissioning. Utilizing the Hotwork International method ensures a reliable and controlled heat source, allowing for efficient and accurate mill commissioning. This approach provides consistent temperature management, minimizing operational risks and optimizing system performance during testing phases.

Read more about mill heating

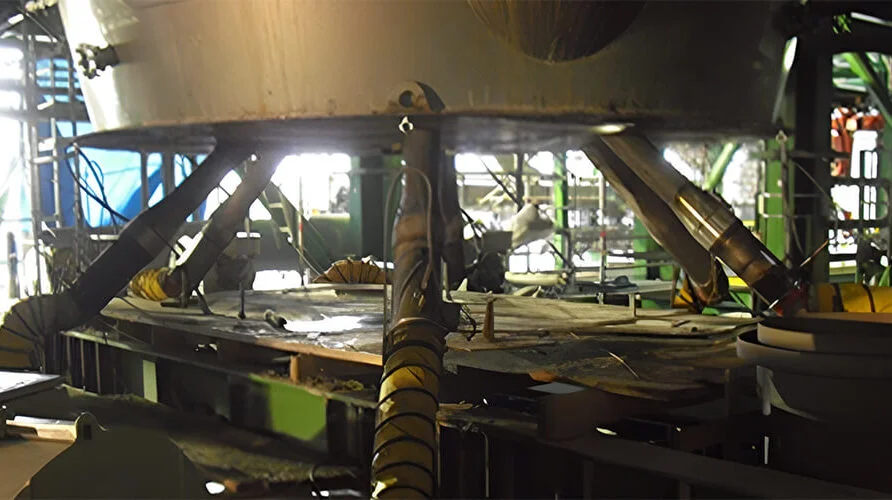

Electrical Dry Out

Hotwork International’s electrical heating mats provide an efficient solution for refractory dry-out without the need for constructing a temporary kiln or furnace to house portable high-velocity burners. These mats can be strategically deployed around the target area, offering precise temperature control and uniform heat distribution. This method is particularly advantageous for drying out main burners or other smaller refractory-lined components, ensuring accuracy and efficiency.

Read more about electrical dry out